Raúl Avezuela, José Moral & Jenifer Serna, EcosimPro/PROOSIS

EcosimPro and the PIPELIQTRAN library have been used to model a large reverse osmosis desalination plant with a maximum output of 16,000 m3/h . The simulation will allow startup and shutdown sequences to be studied with a view to guaranteeing plant stability.

The plant is hydraulically complex for several reasons. First because the tanks between the various subsystems are not large enough, there is a strong hydraulic coupling between them. This means that the startup/shutdown and/or disturbances in a subsystem are transmitted to the rest, which could have an impact on the overall plant stability. Second because the existence of several lines that operate in parallel, and where startup/shutdown of one of them can affect the stability of the others.

The modelled desalination plant has the following subsystems: Intake (seawater intake is located several kilometres away from the plant), Low Pressure Pumping and Pretreatment, LPP+DF+UF (seawater undergoes pretreatment in the desalination plant), SWRO/RO First Stage (the first stage of the reverse osmosis process that has two permeate outputs: Front and Rear Permeate), and BWRO/RO Second Stage (Second reverse osmosis stage, applied on part of the SWRO permeate to attain the required quality).

The EcosimPro model includes the hydraulic modelling of the system to adjust design and control parameters, as well as to identify potential operating problems and to test proposed solutions. The model therefore focuses on studying the pumping and storage systems, including the membranes and energy recovery systems to ensure the quality of the product is adequate. The chemicals that are added in association to the desalination process have not been included because they are not relevant for the study.

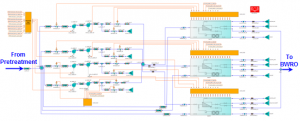

Hereafter is included the model schematic of the first desalination stage, as taken from the overall model where all the stages are interconnected so that their hydraulic coupling can be studied.

The startup and shutdown of each of these lines is analysed to study the validity of the established design parameters, as well as to determine operating parameters such as delays in the startup of the various stages or the parameters that define the different control loops. Accordingly, special attention is paid to avoiding pump cavitation and to keeping them below the run-out flow. With this purpose in mind, the draining in the tanks and the losses due to spillover in those same tanks are avoided.

This study provides the required parameters and relevant conclusions that need to be taken into account during plant operation, such as the following:

• The startup and shutdown of new reverse osmosis lines can cause a drop in the pressure in the rest of the parallel lines, which affects the permeate flow obtained during the transient that occurs until normal operation is reset.

• On some occasions, the pump operating limits that are set out in the design do not ensure the operation at the pump optimum range, so new limits taken from the analysis of the results are suggested.

This study has located required design modifications and improved the accuracy of projected operating parameters, correcting them so as to apply values that are closer to the operating conditions. This information will allow the plant to be started up for testing considering only the equipment that is being used, and to apply parameters that will prevent problems during operation of the desalination plant.