PPTS - Power Plant Transient Simulation

Last Releases

1.0.0

Status

Internal simulation toolkit, not available for sale, only for consultancy and project development

Applications

Modelling systems of a power plant for fossil-fired (Combined Gas Cycle and Coal), nuclear (secondary side), thermosolar and hybrid, and advanced generation (Coal Oxy-combustion)

- Support for equipment sizing and compatibility of power plant components and systems

- Determination of actuator operating speed requirements: valves, pumps and fans

- Facilitate knowledge of the plant response in open-loop for defining the plant control concept

- Check control logics before implementation (“virtual commissioning”)

- Preliminary adjustment of controllers (gains, integration times,…)

- Analysis of Operational Transients of the plant (load switching, changes of operation mode, pump, turbine trips, …)

- Support for plant testing and start-up activities to facilitate problem identification and troubleshooting

- Engineering simulator to support the plant operation activities of the operation engineers

Description

PPTS (Power Plant Transient Simulation), currently an EA International in-house toolkit, provides modelling components to represent the typical hardware and controls of a power plant, currently available for: fossil (Combined Gas Cycle and Coal), nuclear (secondary side), thermosolar and hybrid, and advanced generation (Coal Oxy-combustion).

PPTS models can be used throughout the project development process for supporting different design activities. The models can be used either directly in its development & simulation environment or be easily connected to a Human Machine Interface (HMI) application to develop an engineering and/or partial training simulator. These libraries have been used in several successful application cases.

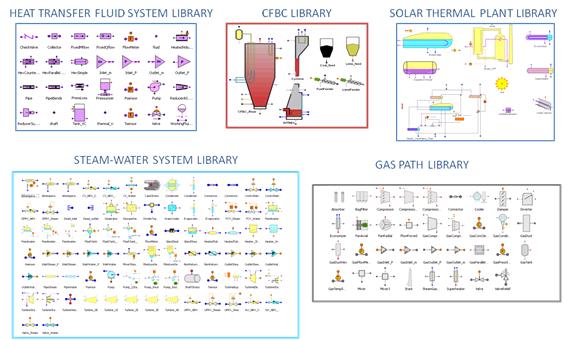

A short description of each library follows:

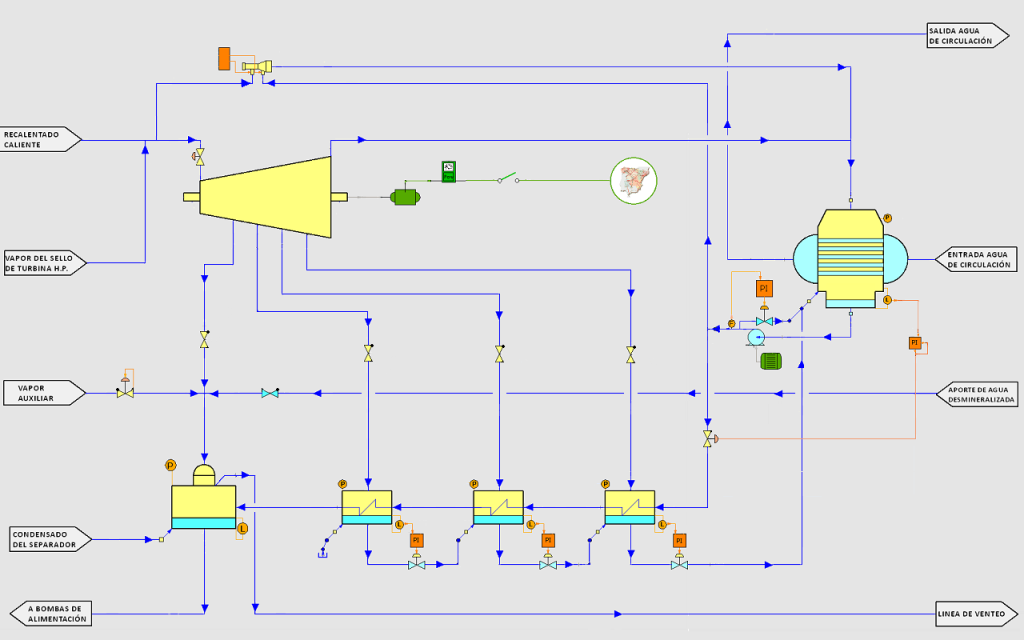

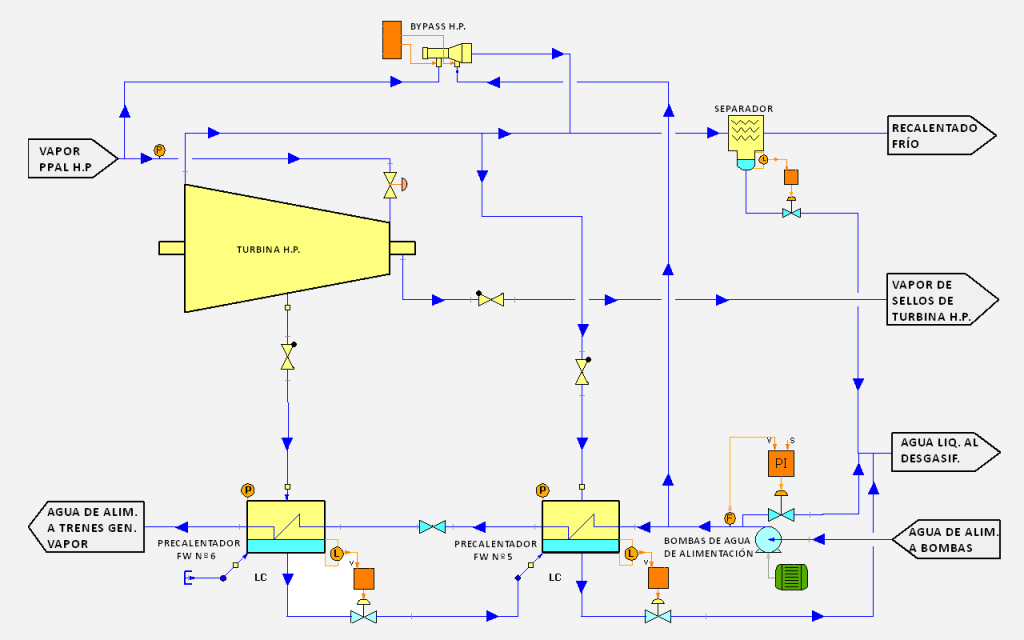

STEAM-WATER SYSTEM Library: This library consists of a set of components that represents the typical plant equipment working only with steam and/or water for modeling Rankine cycles, such as the condenser, feed water heaters, moisture separator, control valves, attemperators, steam and water pipes, etc

GAS PATH Library: This library includes a set of components needed to represent the 1D gas flows in the system, i.e. the flue gas path, oxidant inlets and oxidant re-circulations. Heat exchangers where one of the two sides is gas and the other side is steam and/or water, are part of this library.

CFBC Library: This library consists of a set of components needed to represent a Circulating Fluidized Bed combustor

HEAT TRANSFER FLUID SYSTEM Library: This library is used for representing 1D non-compressible fluid flow. Heat Transfer fluid and refrigeration fluid circuits can be modeled with this library, for example the HTF system of a solar power plant or the primary circuit of a nuclear power plant.

SOLAR THERMAL PLANT Library: Library that includes specific components for modeling thermal solar power plant like currently parabolic trough solar collectors, expansion tanks, auxiliary boilers, etc and mirrors and tower in the next future.

Solar-Thermal Power Plant Simulator

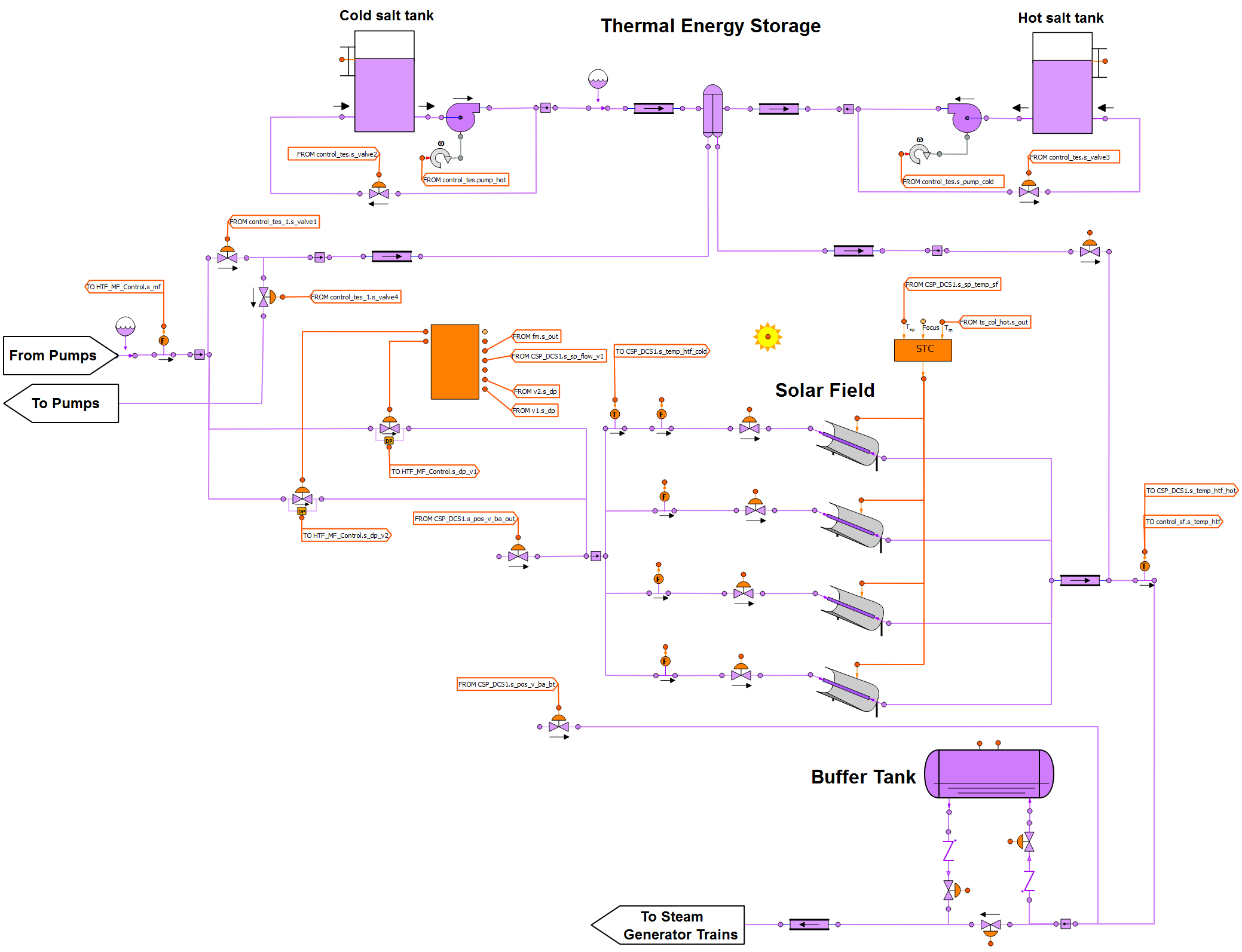

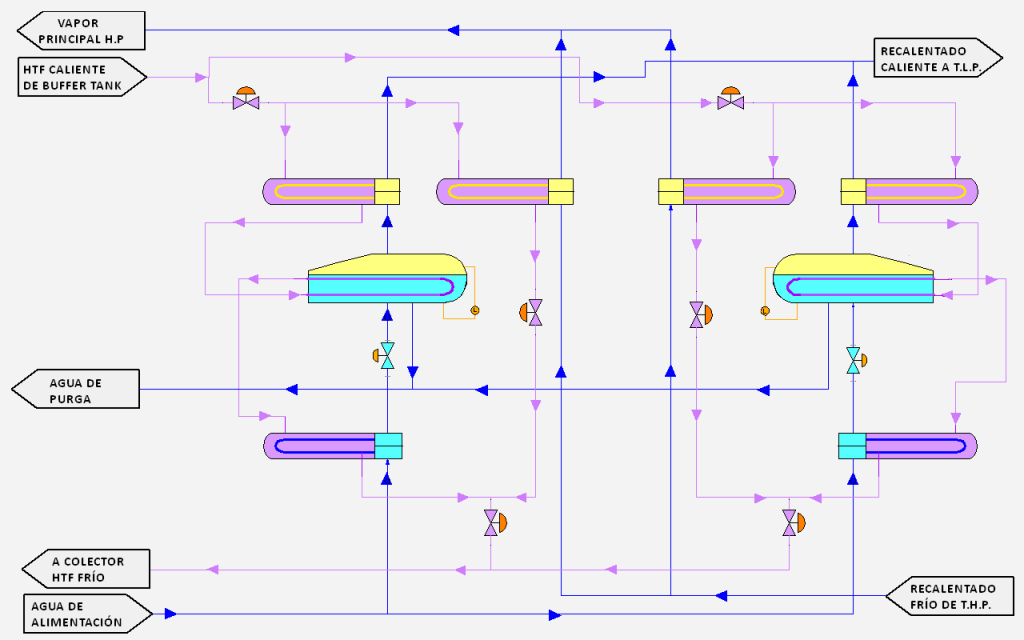

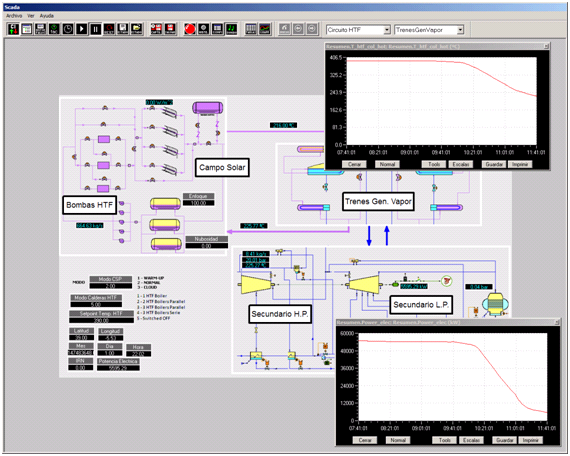

The ST-PPTS libraries have been used for developing a simulator for a solar-thermal power plant with parabolic collectors with thermal energy storage and fossil-fired backup systems in order to study the typical transients of this type of power plants: start-up, shutdown passing clouds, a trip in some equipment, heat transfer from/to the thermal energy storage etc. ST-PPTS is an internal simulation toolkit, not available for sale, only for consultancy and project development.

The simulation model represents the transient behaviour of the following parts of the solar-thermal plant using parabolic collectors:

- Solar field Heat Transfer Fluid (HTF)

- Thermal Energy Storage (TES)

- Steam generation system

- Rankine steam cycle (power block) and circulating water system

- Control sequences and loops and plant operating modes

The following figures show the model schematics of the solar field and the Thermal Energy Storage (TES), the steam generation system and the Rankine steam turbine cycle (power block).

The model also allows simulating the weather conditions (temperature, direct normal solar irradiance, wind speed, etc.) from weather data files. Other main applications include its use in the training of operators and engineers in operating the plant, for support in developing the engineering of the plant and for checking the logics and control sequences before start-up (virtual commissioning).

The simulation model was used to generate an OPC server (Object Linking and Embedding for Process Control) that was then connected to one of the plant’s SCADA systems.

Coal Oxycombustion Power Plant Simulator

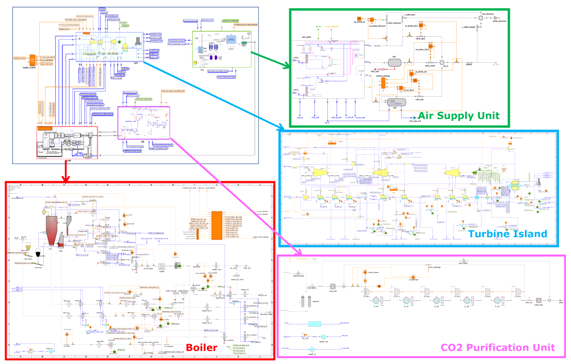

An integrated dynamic model of a power plant with CO2 capture based on a supercritical coal-fed circulated fluidized bed boiler was developed. The model includes different sub-models corresponding to the main process units of the plant:

- The Air Separation Unit (ASU)

- The CO2 Compression and Purification Unit (CPU)

- Detailed models for the boiler and the cycle

- Thermal interaction between ASU/CPU and cycle

- Detailed modelling of the interfaces with the boiler

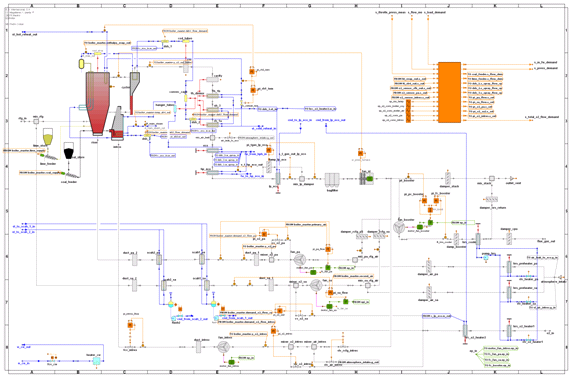

The following figure shows the schematic diagram of the complete power plant model:

The following figure shows the schematic diagram of the sub-model of the circulating fluidized bed boiler.

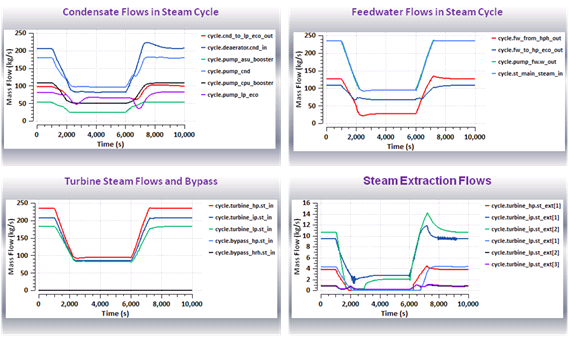

The simulator can simulate a wide range of transient scenarios such as transitions between different operating modes (oxy-combustion mode and fresh air mode), load changes, steam turbine trips, ASU/CPU trips, variation of the purity of O2 in the oxygen stream, etc. The following plots depict the evolution of some of the most significant process variables during the load ramp scenario between 100%-40% and 40%-100%