Almudena Rueda. EcosimPro Applications Team

The scarcity of fresh water has been decried in forums and organizations all over the world. It therefore comes as little surprise that considerable efforts are being made to improve water management. One such endeavor is desalination.

Desalination is a process by which salt and other minerals are removed from water to obtain a product apt for human consumption and for irrigation. Because this type of process requires high energy consumption, one of the objectives of designing and operating desalination plants is to minimize energy costs and make the processes for obtaining fresh water profitable.

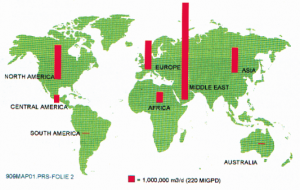

There are currently more than 12,000 desalination plants worldwide, and production of fresh water is expected to rise to 100 million m3/day by 2015.

In this context the usefulness of the new Reverse Osmosis Simulation (ROSIM) library in EcosimPro becomes clear. Developed for EcosimPro by the University of Valladolid, it can be used to simulate desalination processes for studies for optimizing the design and operation of desalination plants.

The library started with the need to simulate reverse osmosis processes, so it has a large number of membranes (simple, with various discharges, discretized, etc.) as well as including components needed for the processes associated with reverse osmosis, the pre- and post- treatment (chemical or pH additives, filtration, pumping, etc.).

But the scope of this library is not limited to processes of reverse osmosis. Rather, it also includes components for simulating thermal desalination processes (Multi Stage Flash (MSF) and Multi Effect Desalination (MED)) as well as energy recovery systems (Dual Work Exchange Energy Recovery (DWEER), Energy Recovery Device (ERD), etc.) and analog components for setting the desired control logic in the process.

Consequently, ROSIM can be used to develop models of complete desalination plants, and by combining their components, hybrid plants, which combine membrane and thermal processes to optimize desalination efficiency.

Some of the most important components are:

- Reverse osmosis membranes: there are several components that represent reverse osmosis membranes to fit the user’s needs, including systems with one or two permeated outlets, discretization of equipment or the use of different types of membranes in a single system

- Filters: it contains many types of filters, classified in terms of particle size (micro-filtration, ultra-filtration, etc.) and sand filters

- Chemical addition: chemical compounds for pre- and post-treatment may be added by using specific components to select the compound to add and its conditions, as well as to connect it to a control loop

- Energy recovery systems: models have been developed for systems such as DWEER (Dual Work Exchange Energy Recovery), ERD (Energy Recovery Device), PRO (Pressure Retarded Osmosis) and turbines

- Hydraulic components: due to the need for using this type of components, the ROSIM library also includes the models of tanks, pipes, valves and pumps, including a large variety of components to fit the user’s needs

- Control elements: the ROSIM library has an ample collection of analog components for creating control loops using sensors, P&IDs, PLCs, etc.

This makes ROSIM a professional library for handling high-level industrial problems. Thanks to its design and implementation, end-users can solve highly complex problems without having to concern themselves over low-level tasks.

The following figure shows the model of a reverse osmosis plant in which ROSIM components are used to portray the complete process. The saltwater stream must first go through a pre-treatment process involving chemical additives and filtration of the homogenized mixture. The pressure of the stream is then raised using a positive displacement pump whose discharge goes directly to the membrane in which the reverse osmosis occurs. The permeated stream than undergoes post-treatment with chemical additives before it reaches the storage tanks. There are various control loops for controlling some of the process variables, such as the pre-treatment loop in which the pH additive varies according to the reading on the pH sensor located after the homogenizer.

EcosimPro Model of an Inverse Osmosis plant: pre-treatment, pressurization, RO membrane and post-treatment.

EcosimPro Model of an Inverse Osmosis plant: pre-treatment, pressurization, RO membrane and post-treatment.