Victor Pordomingo. EcosimPro Applications Team

The new Electric Machines library developed for EcosimPro in 2012 integrates a wide range of electrical components such as machines, transformers, power converters, control algorithms, etc, which makes it very useful for modelling multi-disciplinary systems that involve electrical components.

The new library is closely related to the ELECTRICAL library already included in EcosimPro and has been specially designed for joint use with the CONTROL library and with another new library, still being developed, for renewable energy.

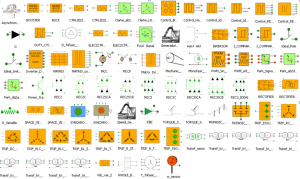

The new Electric Machines library includes the following components:

- The four basic categories of power converters: DC/DC, DC/AC, AC/DC and AC/AC

- Control devices for handling said converters, including PWM and Space vector algorithms

- Set of single-phase and three-phase electric transformers in different configurations based on the analysis of equivalent circuits, including undesired effects

- Set of rotary electric machines: direct current motor, asynchronous induction machine and synchronous machine, all modelled in a reversible manner (motor-generator)

- Mathematical components and coordinate converters suitable for vectorial control of rotary machines and electrical systems

- Electro-mechanical components for increasing the possibility of modelling complete systems with loads and mechanical power sources

The figure below shows the Electric Machines library palette of over 80 components:

The new library, apart from allowing the inclusion of electrical systems in other EcosimPro models, offers the possibility of carrying out simulations of generation systems, responses of drive systems, supply and consumption control, etc.

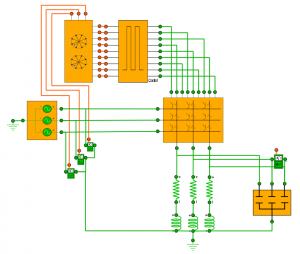

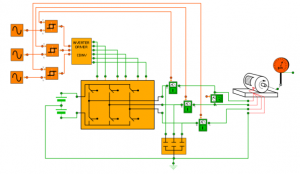

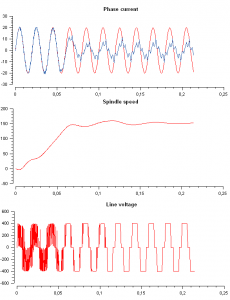

The use of object orientated programming and the possibilities provided by the EcosimPro simulation monitor constitute a very suitable environment for developing electrical models in a simple and intuitive way. By joint modelling with the CONTROL and ELECTRICAL libraries, the user can analyze, for example, the current control on an induction motor (see figure below). The asynchronous three-phase motor is powered by means of an active inverter controlled under current. This is achieved using Relays from the CONTROL library which maintain the current consumed by the motor around a reference value and commutes the poles of the inverter when said current reaches the limits of the hysteresis band. Thus, as can be seen in the graphs below, the machine accelerates up to its stationary speed without the consumption current peaking during startup as would happen if no control were imposed on the system.

Current control model on an induction motor

It also allows the implementation of complex control algorithms that take into account different variables of the model in order to take the right decisions at each instant. The library includes control techniques such as Space Vector modulation and PWM for different types of converters. The figure below shows this technique being applied to a 3×3 AC/AC conversion matrix. This control technique allows the generation of an output voltage whose value is easily controlled, and in addition the consumed current can also be controlled, and therefore so can the power of the system. To do this, two rotating vectors are generated in the Park space. One of them is the voltage reference, while the other is the current reference. Once they have been generated, their rotations are followed and the status of the conversion matrix is decided, as is its application time as a function of the position of both vectors at each instant on the basis of a high frequency carrier signal.