Raúl Avezuela. EcosimPro Applications Team

EcosimPro has been used to develop a complete, integrated dynamic model of a power plant with CO2 capture based on a supercritical coal-fed circulating fluidized bed boiler.

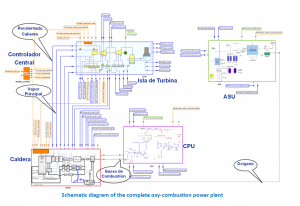

Oxy-combustion is a process that uses pure oxygen instead of air, which makes it possible to concentrate the CO2 from the flue gases and lower their mass flow by almost completely eliminating any nitrogen. The composition of the gases at a coal-fed oxy-combustion plant is mainly CO2 and water. The pure oxygen is normally produced at a conventional technology cryogenic plant called an ASU (Air Separation Unit). Oxy-combustion is a valid process for capturing CO2 at power plants because of the high concentration of CO2 and the reduced mass flow of the flue gases. The flue gas is sent to a plant called the CPU (Compression and Purification Unit), where essentially the concentration of CO2 in the gas is increased and compressed for transport to the storage facility.

Schematic diagram of the complete oxy-combustion power plant

Schematic diagram of the complete oxy-combustion power plant

An oxy-combustion plant is a new kind of industrial facility. At the moment there are only demonstration plants for parts of the process. There is little knowledge regarding how to:

- Control and coordinate the different units making up the plant (boiler, turbine island, ASU and CPU)

- Solve the interface problems with the new units (ASU and CPU)

- Set operating procedures

- Optimize the design and operation

The reason for developing a dynamic model of the oxy-combustion plant in EcosimPro was to have a tool that adds to the creation of knowledge in the areas listed above. This knowledge is essential to trusting that the process works and is controllable before any great investment in building a real plant is made in the future.

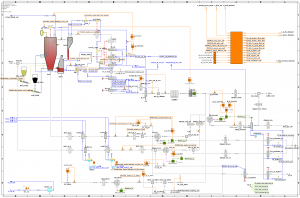

The model portrays the boiler and the cycle in full detail. It is one of the most detailed models on the market for this type of boilers and can be used to calculate stationary states of the plant as well as transient scenarios. The scope of the CPU and ASU models takes into account the thermal integration with the cycle, and special emphasis has been placed on detailed modeling of the interfaces with the boiler.

Schematic diagram of the EcosimPro model of the oxy-combustion circulating fluidized bed boiler

Schematic diagram of the EcosimPro model of the oxy-combustion circulating fluidized bed boiler

The model was used to successfully simulate and analyze the following plant transient scenarios:

- Rise and fall of ramp load from 100% to 40% and back to 100%

- Changing from oxy-combustion mode to air mode and vice-versa

- Trip of the Steam Turbine

- Trip of the ASU plant, which involves loss of production of the low pressure gaseous oxygen and feeding with the auxiliary liquid oxygen vaporization system

- Trip of the CPU plant

- Trip of one of the CO2 compressors without CPU processing

- Variation of the purity of the O2 in the oxygen stream

In addition, the model was satisfactorily verified by comparing the results of stationary states at different plant loads (100%, 80%, 60%, 40%) with the heat balances of the boiler and the whole plant.

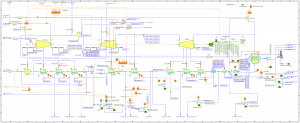

The model has great potential and can be used as a support tool on detail engineering activities of the plant, such as:

- Calculating integral heat balances from the whole plant taking into account the thermal integration between the different subsystems of the plant (boiler, cycle, CPU, ASU)

- Studying different ways of optimizing plant operation

- Optimizing the plant startup and shutdown sequence

- Supporting activities for testing and startup of the plant

- Developing a Training Simulator

Schematic diagram of the EcosimPro model of the turbine island

Schematic diagram of the EcosimPro model of the turbine island

For more information, contact Raúl Avezuela (rao@ecosimpro.com).