GTE-TURBOSHAFT - Gas Turbine Engine Simulations For Power Generation

Last Releases

2.0.1, May 2015

2.0.0, February 2014

Status

Internal simulation toolkit, not available for sale, only for consultancy and project development

Description

Using the existing component and engine libraries (TURBO & GTE-TURBOSHAFT), OEMs, R&D institutes and service providers can quickly define and assess alternative engine concepts (including new or advanced cycles) at the preliminary engine design phase allowing for reduced lead time of new designs. PROOSIS calculations can include design optimization, steady state and transient analyses, water/steam injection and techno-economic studies.

The GTE-TURBOSHAFT library in PROOSIS contains several gas turbine turboshaft engine configurations typically used in industrial applications (e.g. for power generation or mechanical drive) and for marine vessel propulsion. These engine configurations are based on TURBO library components that enable the user to model new configurations. The user can perform both design point and off design calculations as well as to study transients and perform advanced calculations for the control and monitoring of the engine.

Service providers, technology consultancies, power generation and oil and gas companies can use PROOSIS engine decks for engine condition monitoring and perform diagnostic and prognostic simulations, optimize plant operation or assess operation with different fuels.

Please refer to PROOSIS and TURBO for a detailed description of PROOSIS’s capabilities, and gas turbine modeling features.

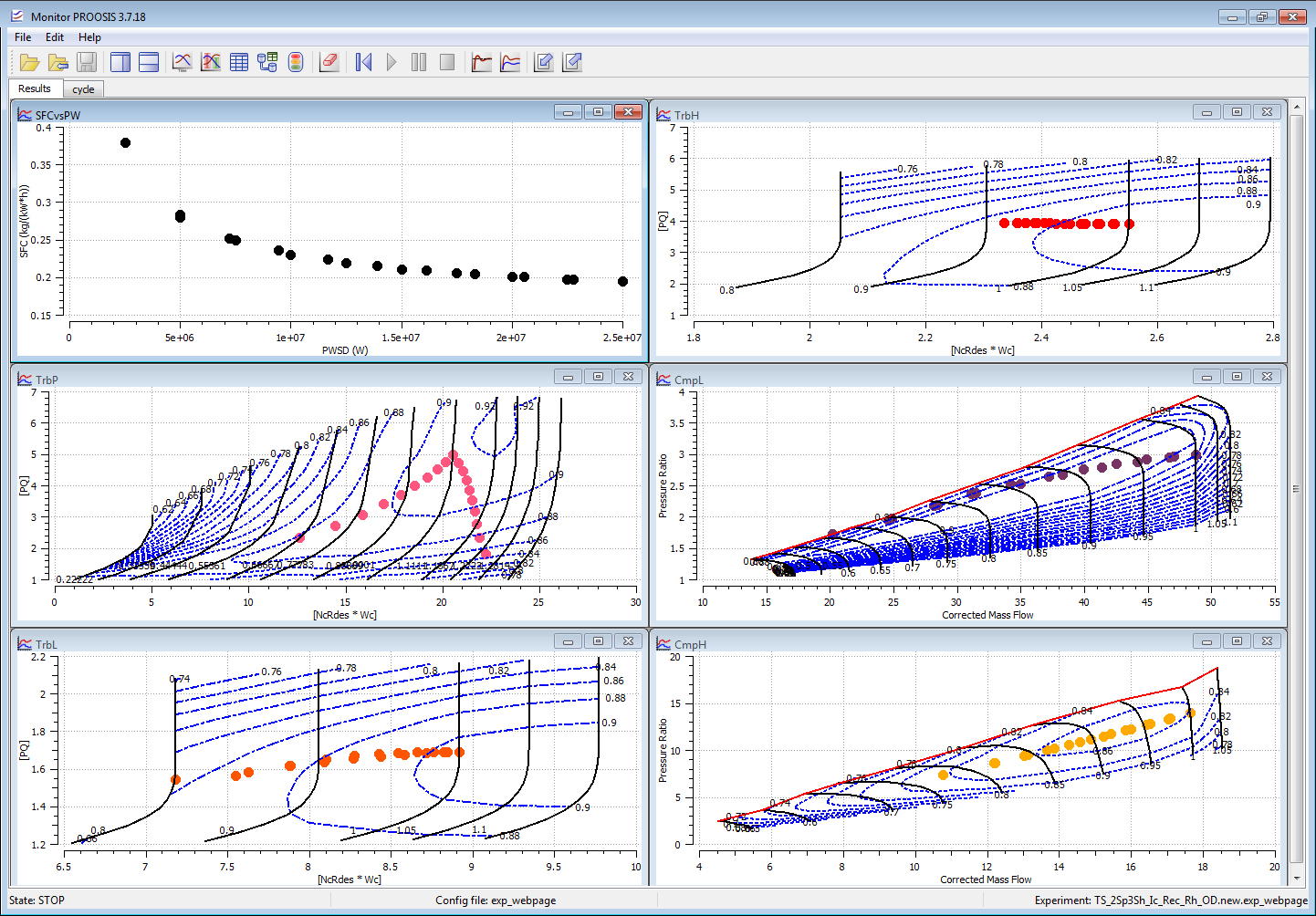

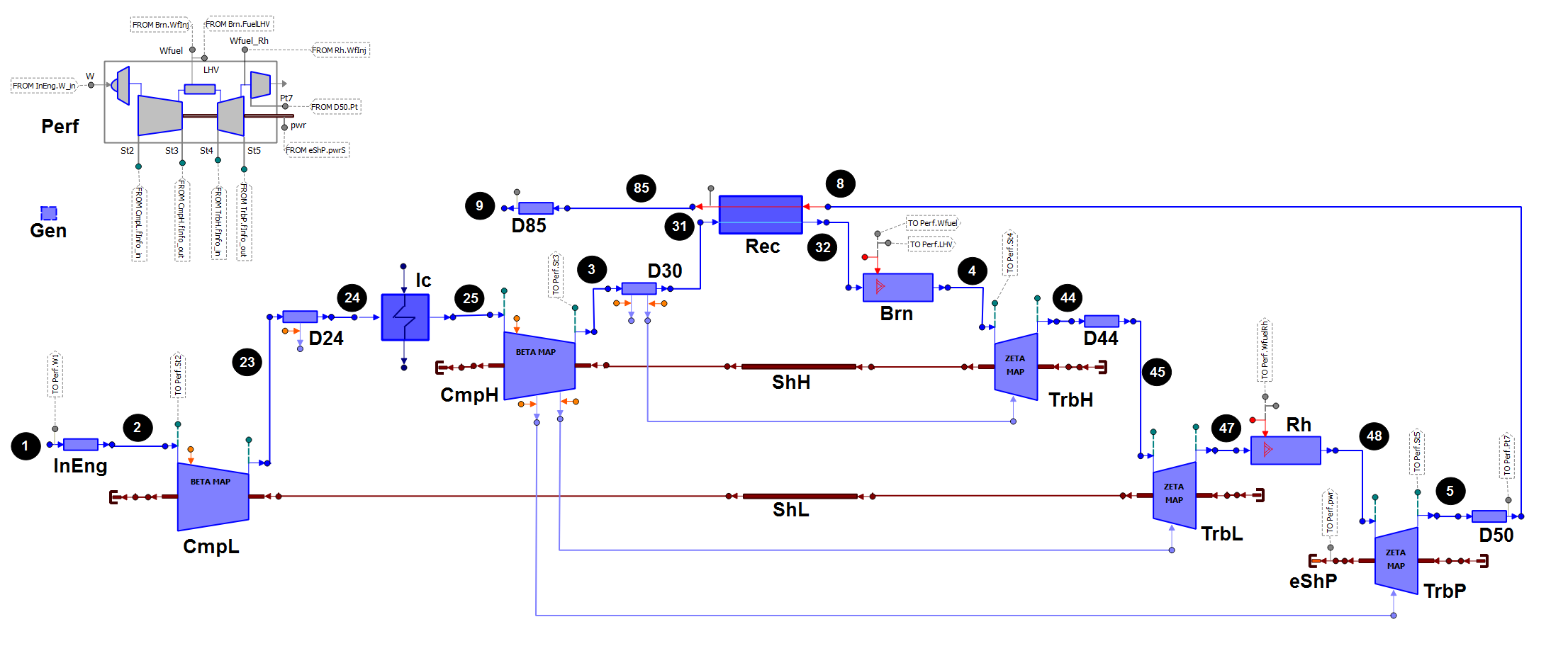

Off-design study of a two-spool, three-shaft engine

This example analyses the off-design behavior of a two-spool, three-shaft with intercooler, recuperator and reheater engine configuration.

The performance of the gas turbine is calculated at different off-design points specified by:

- the intake total pressure Pt1d

- the intake total temperature Tt1d

- the relative humidity RHd

- the shaft power delivered PWSD

- the shaft rotational speed NSD

The results are shown on the turbomachinery component maps. The performance is representative for this engine type where the SFC curve is flat at high power and increases sharply at low power.