ROSIM - Reverse Osmosis Desalination Plant Simulation

Last Releases

1.2.4, January 2022

1.2.3, May 2020

1.2.2, March 2019

User Cases

Product Sheet

Status

Internal simulation toolkit, not available for sale, only for consultancy and project development

Applications

Transient analysis of desalination plants

- Transient studies of desalination plants:

- Reverse Osmosis

- Desalination by Multiple-Effect Distillation (MED)

- Multi-Stage Flash Distillation (MSF)

- Configuration of control loops and their adjustment

- Analysis of pressure drops and reverse flow

- Simulation of pretreatment units: chemical additives and filters

- Study of when a chemical cleaning of the membrane modules should be carried out, and when the modules should be partially or completely replaced.

Description

Reverse Osmosis SIMulation (ROSIM) toolkit is designed to simulate desalination process allowing the user to develop studies for optimizing the design and operation of desalination plants.

The toolkit is mainly focused on reverse osmosis containing a large variety of membranes (simple, with various discharges, etc.) as well as additional components for pre- and post- treatment (chemical or pH additives, filtration, pumping, etc.). It also includes, however, components for simplified simulation of thermal desalination processes such as MSF (Multi Stage Flash desalination) and MED (Multi Effect Desalination) -a detailed simulation library is under way for these processes-, and energy recovery systems such as DWEER (Dual Work Exchange Energy Recovery) and ERD (Energy Recovery Device), etc.

The toolkit has been developed at the University of Valladolid (Spain) and has been validated with experimental data from a pilot plant placed in the Research and Technology Center of Energy (CRTEn), in Tunisia.

Key features:

- Several membrane components:

- 1 or 2 membrane material

- without discretization

- 1D discretization

- The membrane and filter replacement can be set by time or by pressure loss

- Different filter components depending on the particle size

- Working fluid: water with several substances (microorganisms, sustrate, bisulphite, sodium hypochlorite…)

- Reverse flow in hydraulic systems (pipes, tanks)

- Heat transfer in heaters and energy recovery systems

- Existing modules for water pretreatment, containing different chemical additions, DAF (Dissolved Air Flotation), etc.

Reverse Osmosis Membrane

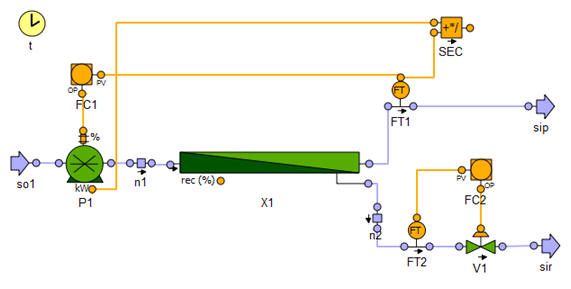

The following user case shows a membrane in which the permeate flow is controlled by the speed of the feed pump.

A salted water stream feeds the membrane. Thanks to pressure difference, pure water traverses the semipermeable membrane obtaining a desalted water stream (permeate) and increasing the salt concentration in the feed side of the membrane (retentate).

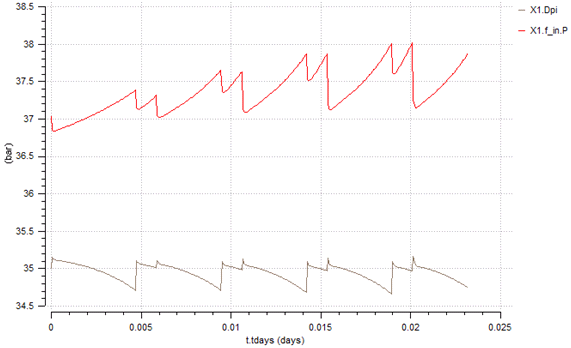

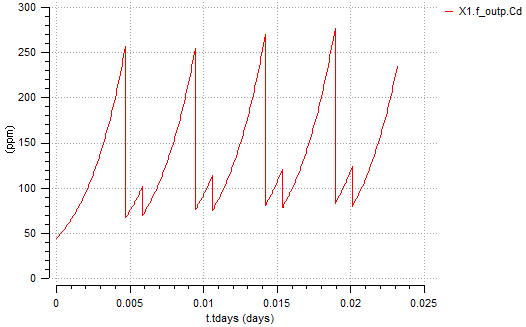

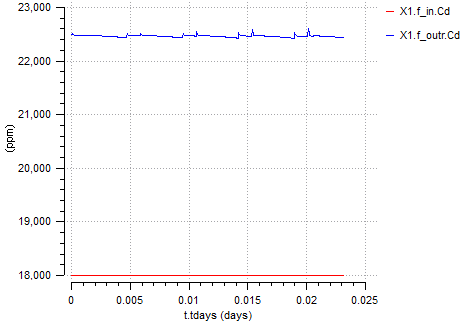

The following plots show the results obtained from the simulation of this model.

Permeate concentration in each stream is affected by membrane cleaning and replacement:

Pressure: every time the membrane is cleaned or replaced, the pressure drop in the membrane decreases.