Ramón Pérez Vara, EA

Empresarios Agrupados was asked to find the root cause of a loss of efficiency in the secondary circuit (Rankine steam cycle) of a power plant.

It was suspected that the duplex heaters of two of the three condensate trains were responsible for the loss of efficiency. Still, although it was fairly certain which equipment were causing the problem, the problem itself was far from solved, because it was necessary to determine the exact failure in order to facilitate inspection of the equipment during refuelling.

A plant energy balance model was developed using EcosimPro and THERMAL BALANCE library to simulate various scenarios with a high degree of approximation to the response of the cycle, both in rated operating conditions and in degraded operating conditions caused by wear or equipment malfunction.

Different equipment degradations and failures were postulated, applying an optimisation algorithm to each degradation or failure. This allowed changing the level of supposed degradation to minimize the difference between the values measured in plant and those calculated. Logically, the most likely cause of the problem would be the one that most reduces the deviation between the measured values and those calculated by the energy balance, after applying the optimisation algorithm.

This fairly simple technique allowed identifying the cause of the failure. During the plant’s refuelling outage, the equipment located in the zones identified by the simulation model was inspected and the exact type of failure that had been predicted by the model was found.

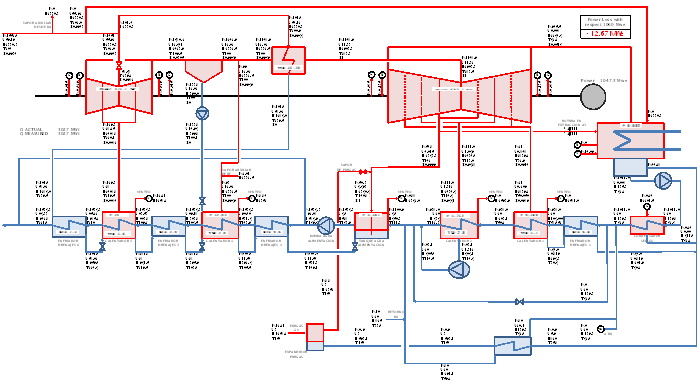

The plant energy balance simulation model developed in EcosimPro was linked to and run on an Excel spreadsheet to make post-processing of the results of the different scenarios easier, as shown in the following figure.

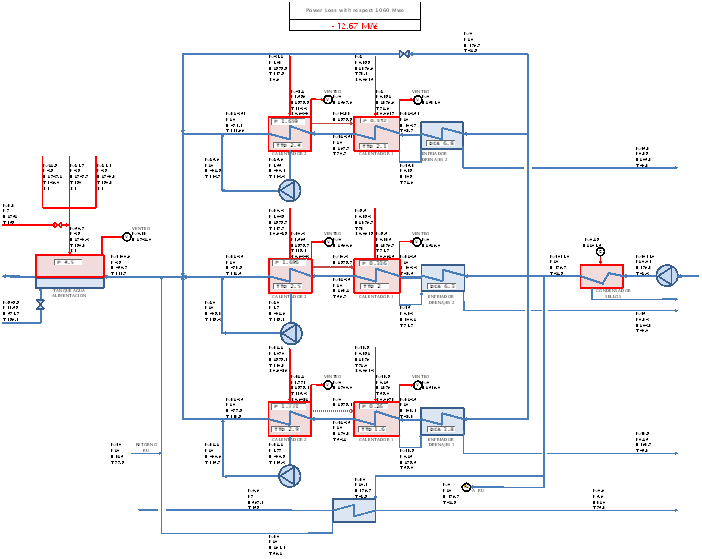

To perform the analysis, a detailed model of the condensate trains had to be developed. The following figure shows the results of the energy balance of the trains supposing an operating failure in them.

It is important to point out that the set of possible errors is not only decided by the model but basically by an expert deciding on the basis of his experience and physical perception. A sophisticated calculation model is a valuable tool but not if used improperly or if its results are poorly interpreted.

In this respect, the heat balance of the plant developed in EcosimPro enabled locating precisely the operating problem/failure in the condensate trains that was affecting the output of the power plant. This study demonstrates the flexibility and usefulness of EcosimPro for evaluating efficiency and power losses in power plants.